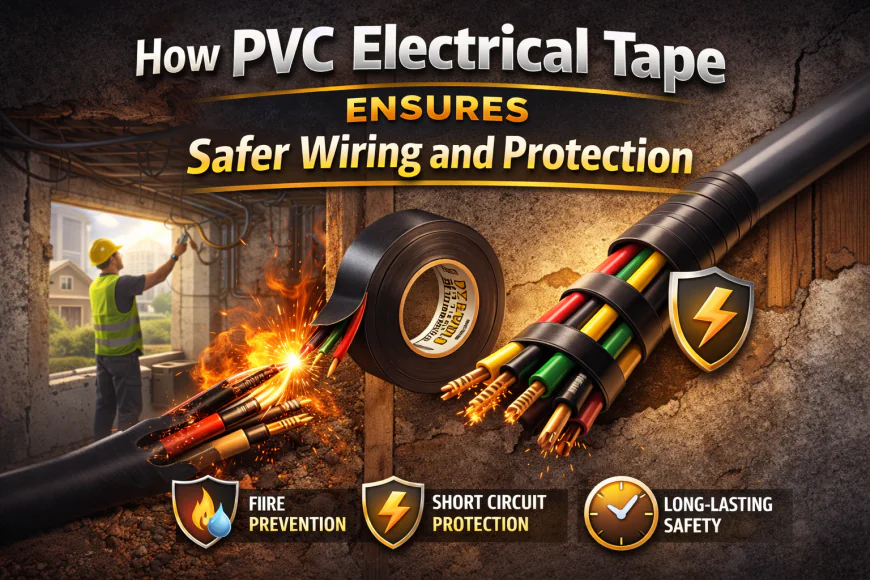

How PVC Electrical Tape Ensures Safer Wiring and Protection

Protect your wiring with PVC Electrical Tape. Learn how proper insulation prevents short circuits, sparks, and fire, while ensuring long-lasting electrical safety in homes, offices, and industrial setups.

Honestly, I’ve seen so many electrical mishaps that could have been prevented with one simple tool, PVC Electrical Tape. In homes, offices, and industrial setups across Pakistan, poorly insulated wires often cause short circuits, sparks, or even small fires. It’s astonishing how often something as simple as proper insulation is overlooked.

PVC Electrical Tape isn’t just sticky plastic; it’s a critical safeguard for electrical safety, wiring durability, and compliance. When installed correctly, it prevents electrical hazards, maintains safe cable routing, and extends the lifespan of wiring systems.

In this article, you’ll learn exactly how PVC Electrical Tape protects wiring, how to choose the right type for your project, proper installation techniques, and maintenance tips to keep your electrical systems safe for years.

Understanding PVC Electrical Tape: More Than Just Adhesive

From my experience working with electricians and DIY enthusiasts, one common mistake is treating electrical tape as a “temporary fix.” In reality, PVC Electrical Tape is engineered to withstand heat, moisture, and mechanical stress.

Key benefits include:

-

Provides short circuit prevention and voltage protection

-

Guards against corrosion and moisture damage

-

Improves long-term wiring durability

-

Supports home, office, and industrial wiring applications

I’ve personally noticed that using high-quality tape like the ones from Adamjee DuraBuilt drastically reduces the risk of loose wires or electrical failures. This is why selecting the right tape is critical for safety and compliance.

Technical & Material Variations of PVC Electrical Tape

Not all PVC tapes are created equal. Depending on your project, different types perform better:

Some are designed for general wiring, while others are heavy-duty, heat-resistant, or flame-retardant, making the choice critical for safety and longevity.

-

Vinyl electrical tape: Flexible, suitable for everyday wiring

-

Heat-resistant PVC tape: Ideal for circuits under heavy load

-

Flame-retardant PVC tape: Protects against accidental sparks and fires

-

Heavy-duty adhesive PVC tape: Industrial-grade protection for high-stress environments

Tips for choosing the right type:

-

Check material composition for insulation quality

-

Use color-coded tapes for easier identification and organization

-

Consider thickness,thicker tapes provide longer-lasting protection

Honestly, I’ve seen electricians stack multiple layers of heavy-duty tape for added protection in industrial setups,it works surprisingly well.

Physical Attributes & Design Features That Affect Performance

When buying PVC Electrical Tape, don’t just focus on price. The physical design and attributes matter: Consider thickness, flexibility, adhesive strength, and moisture resistance, as these factors directly impact performance and durability.

-

Flexibility: Wrap around bends and corners without cracking

-

High adhesion: Prevents tape from peeling over time

-

Waterproof & moisture-resistant: Essential for damp or outdoor wiring

-

Color coding: Helps quickly identify circuits during maintenance

Why it matters:

-

Maintains safe cable routing

-

Protects wiring from abrasion and wear

-

Ensures consistent electrical load safety

For me, choosing tape with proper adhesion and thickness has always been the difference between temporary fixes and long-term safety.

Application-Specific Uses of PVC Electrical Tape

PVC Electrical Tape isn’t one-size-fits-all. Different scenarios require specific approaches:

Residential wiring, industrial installations, automotive circuits, and commercial setups each demand tape with specific material properties and strength.

-

Home wiring: Seal small joints, cover DIY electrical fixes

-

Industrial wiring: Heavy-duty protection for high-voltage circuits

-

Automotive applications: Insulate battery cables and delicate circuits

I remember a project where an office in Karachi had chaotic cabling. After applying PVC Electrical Tape correctly, it not only looked neat but also reduced minor electrical faults by half.

Installation Best Practices for Long-Lasting Results

Even the best tape fails if installed incorrectly. Follow these steps for safe and lasting results:

Always clean the surface, overlap layers properly, avoid overstretching, seal bends, and inspect edges to ensure reliable insulation.

-

Clean and dry the wire surface before wrapping

-

Start at the base and overlap layers by at least 50%

-

Avoid stretching tape too thin; maintain moderate tension

-

Seal joints and bends carefully to avoid gaps

-

Inspect for loose edges after wrapping

Benefits of proper installation:

-

Reduces risk of short circuits and electrical fires

-

Enhances heat and moisture resistance

-

Extends long-term durability of wiring

Frankly, I’ve seen DIY enthusiasts ruin expensive wires simply by stretching tape too thin,so this step is crucial.

Choosing the Right PVC Electrical Tape for Your Project

Factors to consider before purchase: Evaluate environment, voltage requirements, tape type, and supplier reliability, while ensuring compliance with electrical safety standards.

-

Environment: Indoor, outdoor, humid, or dry areas

-

Voltage & electrical compliance: Match tape to circuit requirements

-

Material type: Heat-resistant, flame-retardant, or heavy-duty adhesive

-

Supplier reliability: Brands like Adamjee DuraBuilt ensure quality

Quick checklist:

-

Match tape with the application (residential, industrial, automotive)

-

Ensure the tape is compliant with local safety standards

-

Choose durable and long-lasting material

Maintenance & Inspection Tips for PVC Electrical Tape

Proper care ensures your wiring remains safe: Regularly check for peeling, heat damage, or moisture exposure, and replace worn sections to maintain long-term protection and functionality.

-

Inspect periodically for peeling, moisture, or heat damage

-

Replace worn or compromised tape immediately

-

Avoid low-quality tape that loses adhesion quickly

Maintenance benefits:

-

Maintains short-circuit protection

-

Preserves voltage and insulation safety

-

Extends lifespan of wiring systems

Conclusion: Protect Your Wiring and Prevent Hazards

In short, PVC Electrical Tape is more than a simple accessory,it’s a vital tool that ensures electrical safety, prevents short circuits, and extends the life of your wiring. From residential homes to industrial sites, using the right tape and following proper installation practices makes a real difference in keeping systems safe and reliable over time.

Don’t wait for an electrical mishap to highlight the importance of proper insulation. Investing in high-quality PVC Electrical Tape from Adamjee DuraBuilt, applying it correctly, and checking it periodically ensures decades of worry-free performance for your wiring. Your circuits,and your peace of mind,deserve this level of protection.

Pairing proper wiring safeguards with durable infrastructure, like Pprc Pipe and Fittings, adds an extra layer of safety and reliability to your electrical and plumbing systems. Together, they create a strong, long-lasting setup that protects both your investment and the people who use it daily.

Frequently Asked Questions (FAQs)

What is PVC Electrical Tape used for?

Insulating wires, protecting against moisture, preventing sparks.

How does PVC Electrical Tape improve wiring safety?

By sealing connections, preventing corrosion, and reducing short circuits.

Can PVC Electrical Tape prevent short circuits?

Yes, proper wrapping and quality tape prevent accidental contact.

Which type of PVC tape is best for home wiring?

Vinyl or standard adhesive tape is usually sufficient for residential setups.

How do I apply PVC Electrical Tape for long-lasting results?

Clean the wire, wrap with 50% overlap, seal bends, inspect edges.

Adamjee Durabuilt Pvt Ltd

Adamjee Durabuilt Pvt Ltd