Testing Product Safety: Why It’s Crucial and How It’s Done

Product safety testing is a critical step in delivering high-quality, reliable, and trustworthy products. It protects consumers, safeguards businesses, and ensures compliance with regulations.

In today’s market, consumers expect products to be not just innovative and effective but also safe. From toys and electronics to cosmetics and household items, testing product safety isn’t optional—it’s essential. Unsafe products can harm users, damage brand reputation, and lead to costly recalls. That’s why rigorous testing is a cornerstone of modern manufacturing and product development.

Why Product Safety Testing Matters

Every product we use daily has the potential to cause harm if not tested correctly. For example:

-

Children’s toys with sharp edges or toxic paints can cause injuries or poisoning.

-

Electronics that overheat or short-circuit can cause fires.

-

Cosmetics and skincare products can trigger allergic reactions if harmful chemicals are present.

Testing ensures that products meet safety standards, comply with regulations, and protect consumers. Beyond compliance, it builds trust—customers are more likely to buy from brands that demonstrate responsibility.

Key Types of Product Safety Testing

Product safety testing varies depending on the type of product, but some common approaches include:

1. Chemical Testing

This identifies harmful substances in products. For instance, toys are tested for lead, cadmium, or phthalates, while cosmetics are screened for allergens and irritants. Laboratories use advanced techniques like chromatography and mass spectrometry to detect even trace amounts.

2. Mechanical and Physical Testing

Products that involve movement, pressure, or load—like furniture, appliances, and vehicles—are evaluated for durability and structural integrity. Tests simulate real-life conditions, such as drops, vibrations, or stress, to ensure they won’t break or cause injuries.

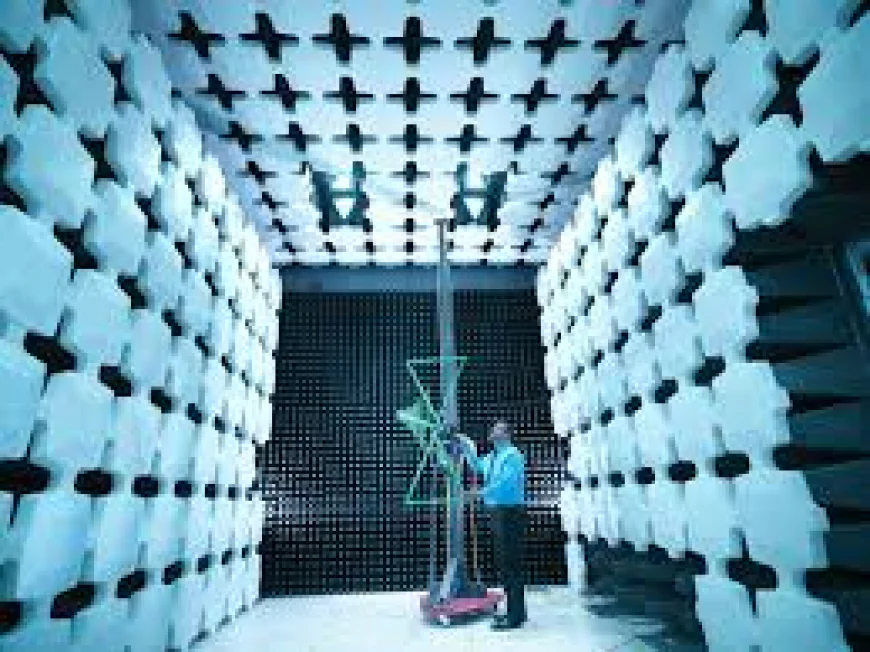

3. Electrical Safety Testing

Electronics undergo rigorous tests for short circuits, overheating, and electrical leakage. Certifications like CE, UL, or FCC indicate that the product meets global safety standards.

4. Microbiological Testing

Especially important for food, beverages, and personal care products, this testing ensures products are free from bacteria, mold, and other pathogens that could harm consumers.

5. Toxicological Evaluation

Some products contain chemicals that may be absorbed by the skin or ingested. Toxicological tests evaluate potential risks and determine safe exposure levels for humans.

How Product Safety Testing Is Conducted

Testing is often a multi-step process:

-

Design Evaluation – Engineers review the product’s design for potential hazards before production begins.

-

Prototyping and Lab Testing – Early versions are tested under controlled conditions to identify weaknesses.

-

Field Testing – Products are used in real-world conditions to observe actual performance.

-

Certification – Independent third-party labs verify compliance with industry standards.

-

Ongoing Quality Control – Even after launch, products are continuously monitored to maintain safety standards.

Regulatory Standards and Compliance

Different industries follow specific safety standards. For example:

-

CPSC (Consumer Product Safety Commission) in the U.S. regulates toys, household items, and consumer electronics.

-

ISO (International Organization for Standardization) provides international standards across multiple sectors.

-

FDA (Food and Drug Administration) oversees cosmetics, pharmaceuticals, and medical devices.

Adhering to these standards is not only legally required in many cases but also demonstrates a commitment to consumer safety.

The Business Benefits of Safety Testing

Investing in product safety testing is more than just a regulatory checkbox—it’s smart business:

-

Reduces Liability Risks – Prevents accidents, lawsuits, and recalls.

-

Enhances Brand Reputation – Builds customer trust and loyalty.

-

Improves Product Quality – Testing often reveals design improvements that enhance performance.

-

Opens Global Markets – Many countries require certified safety testing before products can be sold.

Conclusion

Product safety testing is a critical step in delivering high-quality, reliable, and trustworthy products. It protects consumers, safeguards businesses, and ensures compliance with regulations. For companies serious about long-term success, investing in thorough safety testing isn’t just a precaution—it’s a competitive advantage.

Whether you are a manufacturer, retailer, or product developer, understanding and implementing robust safety testing practices is key to delivering products that customers can use with confidence. After all, a safe product is not only a legal requirement—it’s a promise of care and responsibility.

adamjohn

adamjohn