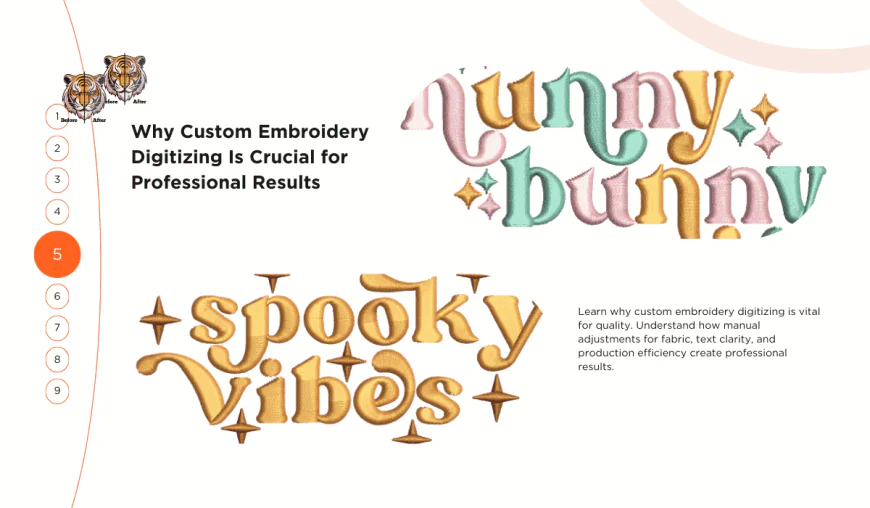

Why Custom Embroidery Digitizing Is Crucial for Professional Results

Learn why custom embroidery digitizing is vital for quality. Understand how manual adjustments for fabric, text clarity, and production efficiency create professional results.

In the competitive landscape of corporate branding and custom apparel, the quality of your merchandise speaks volumes about your business. A logo embroidered on a uniform is often the first thing a customer notices. If that logo is puckered, distorted, or hard to read, it sends a subconscious message of carelessness. Conversely, a crisp, clean, and dimensional logo signals professionalism and attention to detail. The secret to achieving that high-end look lies entirely in custom embroidery digitizing.

Many assume that modern technology allows machines to simply "read" an image and sew it out perfectly. This is a misconception. Embroidery machines are blind tools; they simply follow coordinates. The digitizer is the architect who plots those coordinates. Relying on automated software or generic files often leads to mediocre results because computers lack the intuition to understand how thread interacts with fabric. Custom digitizing is the manual, deliberate process of engineering a design file to suit specific materials, ensuring the final output is flawless.

We will examine why this specialized service is indispensable for anyone seeking truly professional embroidery results.

The Limitation of Automated Conversion

The primary reason custom embroidery digitizing is essential is that art files and stitch files speak different languages. A JPEG or vector file is made of pixels or mathematical lines, which have no physical mass. Embroidery is made of thread, which has thickness, texture, and tension. When you use automated software to convert a design, the computer attempts to fill shapes with stitches without regard for the physical consequences.

A human digitizer creates a file with structural integrity. They manually determine the sequence of stitching to ensure the fabric remains stable. They place "underlay" stitches the hidden foundation to bind the fabric to the stabilizer before the visible top stitches are applied. This foundation prevents the design from sinking into the fabric or shifting during the high-speed sewing process. Without this custom architectural planning, designs often look flat, messy, or misaligned.

Adapting to Fabric Physics

One of the most critical aspects of professional embroidery is the management of the "push and pull" phenomenon. Every time a needle penetrates the fabric, it displaces fibers. Thousands of stitches create significant tension that pulls the fabric in certain directions and pushes it in others. A perfectly round circle on a computer screen will sew out as an oval if these forces are not counteracted.

Custom embroidery digitizing involves adjusting the design to compensate for these physical forces. A skilled digitizer knows that a pique knit polo shirt stretches differently than a stiff denim jacket. For the polo, they will add specific compensation and structural support to prevent the fabric from bunching up around the logo. For the denim, they might reduce the density to prevent needle breakage. This material-specific customization is the only way to guarantee a consistent, professional appearance across different types of garments.

Efficiency and Production Speed

For businesses, time is a tangible resource. A poorly digitized file is a production nightmare. It causes frequent thread breaks, requiring the machine operator to stop, re-thread the needle, and back up the machine. It may also include unnecessary "trims" and "jumps," where the machine slows down to cut the thread and move to a new location. These inefficiencies accumulate, slowing down production runs and increasing labor costs.

Professional custom digitizing focuses on "pathing," which is the route the needle takes through the design. An expert plans a continuous path that minimizes stops and trims. By hiding traveling stitches underneath the design, they keep the machine running at a steady rhythm. This results in a cleaner look on the finished garment with fewer loose thread tails to trim by hand and significantly faster turnaround times for the production team.

Clarity in Small Details and Text

The true test of embroidery quality is legible text. Corporate logos often include taglines or website URLs that are quite small. If these are digitized using standard settings, the thread will bunch up, closing the loops in letters like "e" and "a," rendering the text unreadable.

Custom embroidery digitizing addresses this by manipulating the font structure. A professional will manually widen the gaps between letters and thin out the columns to account for the width of the thread. They prioritize clarity over a strict adherence to the original font file. This subtle manipulation ensures that even at small sizes, the text remains crisp and readable. This attention to detail is what separates a professional, high-end garment from a cheap-looking giveaway item.

Conclusion

Investing in custom embroidery digitizing is an investment in your brand's reputation. While it may be tempting to use free auto-digitizing tools to save a few dollars, the cost of ruined garments and a damaged professional image is far higher. A custom-digitized file is a carefully engineered set of instructions that respects the physics of the material and the limitations of the machinery.

By partnering with a skilled digitizer, you ensure that your logo is reproduced with accuracy, durability, and elegance. It transforms a simple marketing asset into a mark of quality that enhances the perceived value of your apparel and your business.

FAQs

Q: Can I use one custom digitized file for all my garments?

No, this is a common mistake. A file digitized for a flat, stable material like a backpack will not work well on a stretchy, unstable material like a beanie. You should request specific files for different garment types to ensure professional results on each.

Q: Why does my logo look different on the screen than on the shirt?

The screen displays a digital simulation, usually a perfect vector. The shirt displays physical thread. Thread has texture and reflects light, and it sits on top of fabric that has its own texture. A custom digitizer adjusts the file to make the physical result look as close to the digital concept as possible, but the mediums are fundamentally different.

Q: Does custom digitizing affect the durability of the embroidery?

Yes, significantly. Proper digitizing ensures that the stitches are anchored correctly into the fabric. Poorly digitized designs often have loose stitches that snag easily or density issues that cause the fabric to tear over time.

Q: How long does the custom digitizing process take?

Most professional services offer a turnaround time of 24 to 48 hours. This allows the digitizer enough time to plan the pathing, apply the correct settings, and often run a test sew-out to verify the quality before sending the final file.

Q: What is the difference between "flat" and "puff" digitizing?

Flat embroidery lies directly on the fabric. Puff embroidery uses a piece of foam underneath the stitches to create a 3D relief effect. Puff requires a completely different digitizing technique, including "capping" the ends of letters to hide the foam, and cannot be achieved with a standard flat file.